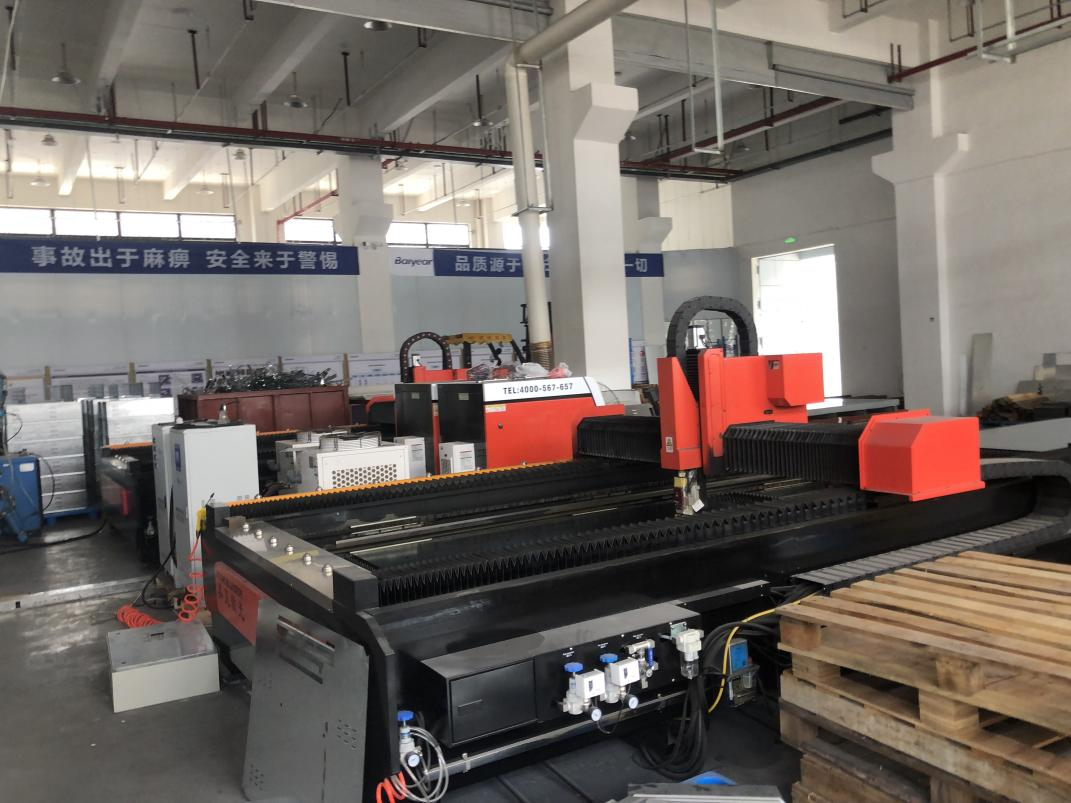

Los ntawm Andy los ntawm Baiyear Hoobkas

Tshaj tawm rau lub Kaum Ib Hlis 1, 2022

Sheet hlau tseem tsis tau muaj cov ntsiab lus tiav.Raws li cov lus txhais hauv phau ntawv xov xwm txawv teb chaws, nws tuaj yeem txhais tau tias: Cov ntawv hlau yog cov txheej txheem ua haujlwm txias rau cov hlau nyias (feem ntau hauv qab 6 hli), suav nrog shearing, xuas nrig ntaus / txiav / sib xyaw, folding, vuam, riveting, splicing , sib sau ua ke (xws li lub tsheb lub cev), thiab lwm yam. Nws zoo kawg li feature yog tias lub thickness ntawm tib seem yog tib yam.

Sheet hlau txiav yog txheej txheem tseem ceeb rau kev tsim cov khoom siv hlau.Nws suav nrog cov tsoos txiav, blanking, khoov txoj kev thiab lwm txoj kev thiab cov txheej txheem tsis, nrog rau ntau yam txias stamping tuag cov qauv thiab cov txheej txheem tsis, ntau yam khoom siv ua haujlwm thiab cov txheej txheem kev ua haujlwm, nrog rau cov tshuab stamping tshiab thiab thev naus laus zis tshiab.

Rau txhua daim ntawv hlau, nws muaj cov txheej txheem ua tiav, uas yog hu ua txheej txheem thev naus laus zis.Nrog rau qhov sib txawv ntawm cov qauv ntawm cov ntawv hlau, cov txheej txheem thev naus laus zis yuav txawv, tab sis tag nrho tsis tshaj cov ntsiab lus hauv qab no.

1. Tsim thiab kos duab kos duab ntawm nws daim ntawv hlau qhov chaw, tseem hu ua peb txoj kev pom.Nws txoj haujlwm yog qhia cov qauv ntawm nws cov ntawv hlau los ntawm kev kos duab.

2. Kos ib daim duab nthuav dav.Uas yog, nthuav ib feem nrog ib tug complex qauv rau hauv ib lub tiaj tus.

3. Ncua tseg.Muaj ntau txoj hauv kev ntawm blanking, feem ntau nyob rau hauv cov hauv qab no:

ib.Shearing tshuab txiav.Nws yog siv lub tshuab shearing los txiav cov duab, qhov ntev thiab qhov dav ntawm daim duab nthuav dav.Yog hais tias muaj kev xuas nrig ntaus thiab kaum txiav, ces tig lub tshuab xuas nrig ntaus kom muab cov xuas nrig ntaus thiab kaum txiav rau daim ntawv.

b.Punch blanking.Nws yog siv cov xuas nrig ntaus rau lub tiaj tus qauv tom qab cov khoom tau nthuav tawm ntawm lub phaj hauv ib lossis ntau kauj ruam.Nws muaj qhov zoo ntawm cov txiv neej luv luv-teev, kev ua haujlwm siab, thiab tuaj yeem txo cov nqi ua haujlwm.

c.NC CNC tshuab dhos.Thaum NC blanking, thawj kauj ruam yog sau CNC machining program.Nws yog siv cov programming software los sau cov kos duab nthuav dav rau hauv qhov kev pab cuam uas tuaj yeem lees paub los ntawm NC CNC machining tshuab.Cia nws ua raws li cov kev pab cuam no los ntawm kauj ruam ntawm lub phaj hlau On, xuas nrig ntaus tawm cov qauv ntawm nws qhov chaw tiaj tus.

d.Laser txiav.Nws siv txoj kev txiav laser txiav cov qauv zoo ntawm nws qhov chaw tiaj tus ntawm lub phaj hlau.

4. Flanging thiab tapping.Flanging tseem hu ua qhov drilling, uas yog kos ib lub qhov loj me me ntawm lub hauv paus me me, thiab tom qab ntawd coj mus rhaub lub qhov.Qhov no tuaj yeem ua kom nws lub zog thiab tsis txhob swb.Feem ntau siv rau cov ntawv hlau ua nrog cov phaj nyias nyias.Thaum lub phaj thickness loj, xws li phaj thickness saum 2.0, 2.5, thiab lwm yam, peb tuaj yeem coj mus rhaub ncaj qha yam tsis muaj flanging.

5. Punch ua haujlwm.Feem ntau, xuas nrig ntaus thiab kaum txiav, xuas nrig ntaus blanking, xuas nrig ntaus convex hull, xuas nrig ntaus thiab rhuav, xuas nrig ntaus thiab lwm txoj kev ua haujlwm yog siv los ua kom tiav lub hom phiaj ua.Kev ua haujlwm yuav tsum muaj cov pwm sib thooj kom ua tiav cov haujlwm.Muaj convex hull pwm rau punching convex hulls, thiab tsim kua muag molds rau xuas nrig ntaus thiab tearing.

6. Siab riveting.Raws li peb lub Hoobkas muaj kev txhawj xeeb, lub siab riveting studs, siab riveting ceev, siab riveting screws, thiab lwm yam. yog feem ntau siv.Riveted rau daim hlau qhov chaw.

7. Khoov.Kev khoov yog txhawm rau quav 2D tiaj tus rau hauv 3D qhov chaw.Nws cov txheej txheem yuav tsum muaj lub tshuab dabtsi yog khoov thiab cov khoom sib dhos sib dhos kom tiav cov haujlwm.Nws kuj muaj qee yam dabtsi yog khoov ib ntus.Thawj qhov quav uas tsis cuam tshuam yuav ua rau cov quav tom kawg uas cuam tshuam.

8. Vuam.Vuam yog siv ntau qhov chaw ua ke kom ua tiav lub hom phiaj ntawm kev ua haujlwm lossis vuam sab seam ntawm ib feem kom nws muaj zog.Cov txheej txheem txheej txheem feem ntau suav nrog cov hauv qab no: CO2 roj shielded vuam, argon arc vuam, Spot vuam, neeg hlau vuam, thiab lwm yam.Feem ntau hais lus, CO2 roj shielded vuam yog siv rau hlau phaj vuam;argon arc vuam yog siv rau txhuas phaj vuam;neeg hlau vuam yog tsuas yog siv rau hauv cov khoom Nws yog siv thaum lub sij hawm loj thiab vuam seam ntev.Xws li cov txee vuam, cov neeg hlau vuam siv tau, uas tuaj yeem txuag tau ntau txoj haujlwm thiab txhim kho kev ua haujlwm thiab vuam zoo.

9. Kev kho deg.Kev kho deg feem ntau suav nrog phosphating zaj duab xis, electroplating multicolored zinc, chromate, ci xim, oxidation, thiab lwm yam. Phosphating zaj duab xis feem ntau yog siv rau cov ntawv txias-dov thiab electrolytic los xij, thiab nws txoj haujlwm yog tsuas yog los npog cov khoom siv.Cov yeeb yaj kiab tiv thaiv yog siv los tiv thaiv oxidation;Qhov thib ob yog los txhim kho qhov adhesion ntawm nws cov xim ci.Electroplating cov yeeb yuj zinc feem ntau yog siv rau kev kho mob ntawm daim hlau txias-dov;chromate thiab oxidation feem ntau yog siv rau saum npoo ntawm txhuas daim hlau thiab txhuas profiles;nws qhov tshwj xeeb nto Qhov kev xaiv ntawm kev ua tiav yog txiav txim siab raws li tus neeg siv khoom xav tau.

10. Kev sib dhos.Lub npe hu ua kev sib dhos yog sib sau ua ke ntau qhov chaw lossis cov khoom sib xyaw ua ke hauv ib txoj hauv kev los ua kom tiav cov khoom tiav.Ib yam uas yuav tsum tau them sai sai rau yog kev tiv thaiv ntawm cov khoom, tsis khawb thiab pob.Kev sib dhos yog kauj ruam kawg hauv kev ua tiav cov khoom siv.Yog tias cov khoom siv tsis tuaj yeem siv vim yog khawb thiab pob, nws yuav tsum tau rov ua dua thiab rov ua dua, uas yuav ua rau lub sijhawm ua haujlwm ntau thiab nce tus nqi ntawm cov khoom.Yog li ntawd, tshwj xeeb yuav tsum tau them rau kev tiv thaiv ntawm cov khoom.

Post lub sij hawm: Nov-29-2022