Dab tsi yog hom kev txhaj tshuaj molding khoom?

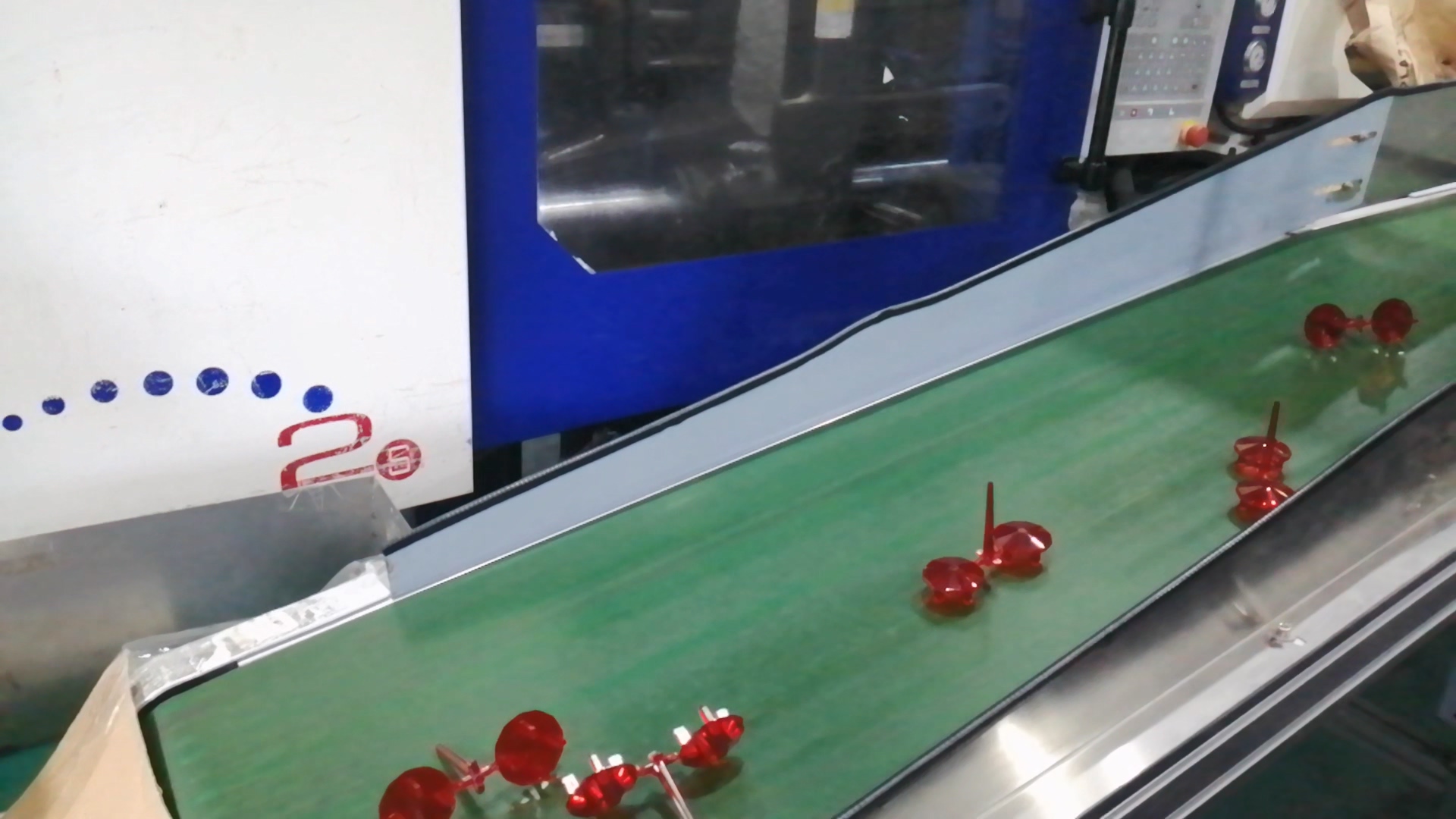

Txhaj tshuaj molding yog txheej txheem tsim khoom uas koom nrog kev txhaj tshuaj molten rau hauv pwm kab noj hniav kom tsim tau cov duab uas xav tau.Kev txhaj tshuaj molding tuaj yeem siv los tsim ntau yam khoom, xws li cov khoom yas, cov khoom siv hlau, cov khoom siv kho mob, thiab lwm yam.Txawm li cas los xij, tsis yog txhua cov ntaub ntawv tsim nyog rau kev txhaj tshuaj molding.Peb yuav tham txog hom kev txhaj tshuaj molding cov ntaub ntawv thiab lawv cov khoom, qhov zoo, thiab qhov tsis zoo.

Hom kev txhaj tshuaj molding cov ntaub ntawv

Muaj ntau hom kev txhaj tshuaj molding cov ntaub ntawv, tab sis lawv tuaj yeem muab faib ua plaub pawg: thermoplastics, thermosets, elastomers, thiab hlau.

Cov thermoplastics

Thermoplastics yog cov khoom siv uas tuaj yeem rov ua dua thiab ua kom khov los ntawm cua sov thiab txias.Lawv yog cov khoom siv ntau tshaj plaws ntawm kev txhaj tshuaj molding, suav txog li 80% ntawm kev ua lag luam.Thermoplastics muaj qhov yooj yim, durability, thiab recyclability.Qee qhov piv txwv ntawm thermoplastics yog:

- Polyethylene (PE): Cov khoom siv uas tsis muaj nqi uas muaj cov tshuaj tiv thaiv zoo, noo noo, thiab cuam tshuam.Nws yog dav siv rau kev ntim khoom, ntim khoom, cov khoom ua si, thiab cov kav dej.

- Polypropylene (PP): Cov khoom siv muaj zog, muaj zog, thiab kub tsis kam.Nws yog siv rau cov khoom siv tsheb, khoom siv kho mob, rooj tog zaum, thiab khoom siv.

- Polyvinyl chloride (PVC): Cov khoom siv hluav taws xob zoo, nplaim hluav taws kub, thiab huab cua.Nws yog siv rau hluav taws xob cables, kav dej, fittings, thiab flooring.

- Polystyrene (PS): Cov khoom siv uas muaj qhov pom tseeb zoo, nruj, thiab qhov ruaj khov.Nws yog siv rau cov khob pov tseg, phaj, cutlery, thiab ntim khoom.

- Acrylonitrile butadiene styrene (ABS): Cov khoom siv uas muaj kev cuam tshuam zoo zog, tawv, thiab nto tiav.Nws yog siv rau vaj tse, kaus mom hlau, khoom ua si, thiab suab paj nruag.

- Nylon: Cov khoom siv uas muaj kev puas tsuaj zoo, hnav tsis kam, thiab cov khoom siv kho tshuab.Nws yog dav siv nyob rau hauv kev sib tsoo, bearings, bushings, thiab fasteners.

Thermosets

Thermosets yog cov ntaub ntawv uas dhau los ua cov tshuaj tiv thaiv thaum tshav kub kub thiab tsim ib qho chaw ruaj khov uas tsis tuaj yeem rov ua dua lossis rov ua dua.Cov thermosets muaj cov thermal stability, tshuaj tiv thaiv, thiab txhua yam muaj zog.Qee qhov piv txwv ntawm thermosets yog:

- Epoxy: Cov khoom siv uas muaj cov nplaum zoo heev, hluav taws xob rwb thaiv tsev, thiab tiv thaiv corrosion.Nws yog siv rau coatings, adhesives, laminates, thiab composites.

- Phenolic: Cov khoom siv uas muaj cua sov ua haujlwm, nplaim hluav taws kub, thiab hardness.Nws yog siv rau hluav taws xob hloov hluav taws xob, qhov (sockets), plugs, thiab tes tuav.

- Polyester: Cov khoom siv uas muaj qhov hloov tau zoo, ua haujlwm ntev, thiab huab cua.Nws yog siv rau lub nkoj hulls, tsheb lub cev, tso tsheb hlau luam, thiab cov kav dej.

- Urea formaldehyde: Cov khoom siv uas muaj tus nqi qis, siab tawv, thiab zoo qhov ntev.Nws yog siv rau pob qhov rooj, khawm,

tuav, thiab rooj tog.

Elastomers

Elastomers yog cov ntaub ntawv uas tuaj yeem ncab lossis compressed thiab rov qab mus rau lawv qhov qub thaum lub zog raug tshem tawm.Elastomers muaj siab elasticity,

resilience, thiab shock absorption.Qee yam piv txwv ntawm elastomers yog:

- Silicone: Cov khoom siv uas muaj cua sov zoo, tiv thaiv ozone, thiab biocompatibility.Nws yog siv rau cov ntsaws ruaj ruaj, gaskets, tubing, thiab cov khoom siv kho mob.

- Roj Hmab: Cov khoom siv uas muaj kev puas tsuaj zoo, kev qaug zog, thiab kev co damping.Nws yog siv rau cov log tsheb, siv, hoses, thiab grommets.

- Thermoplastic elastomers (TPEs): Cov khoom siv sib xyaw ua ke ntawm cov khoom siv thermoplastics thiab elastomers.Nws tuaj yeem ua tiav zoo li cov thermoplastics, tab sis muaj qhov yooj thiab elasticity ntawm elastomers.Nws yog siv rau grips, bumpers, mats, thiab seals.

Hlau

Cov hlau yog cov ntaub ntawv uas muaj cov conductivity siab, ntom, thiab melting point.Lawv feem ntau yog txhaj rau hauv pwm siv cov txheej txheem tshwj xeeb hu ua hlau txhaj tshuaj molding (MIM). pwm.Qhov molded yog ces rhuab kom tshem tawm cov binders thiab sintered los ua ib tug ntom hlau ib feem.MIM tuaj yeem tsim cov duab nyuaj nrog siab precision, nto tiav, thiab cov khoom siv kho tshuab.Qee yam piv txwv ntawm cov hlau uas siv tau rau MIM yog:

- Stainless hlau: Cov khoom siv uas muaj kev tiv thaiv corrosion siab, muaj zog, thiab tawv.

- Titanium: Cov khoom siv uas muaj zog-rau-hnyav piv, bio-compatibility, thiab tshav kub tsis kam.

- Hlau: Cov khoom siv uas tsis muaj nqi, cov khoom sib nqus, thiab hnav tsis kam.Nws yog siv rau cov khoom siv tsheb, cov cuab yeej hluav taws xob, lub zog, thiab cov kabmob.

Xaus

Kev txhaj tshuaj molding yog ntau yam txheej txheem uas tuaj yeem tsim ntau yam khoom siv ntau hom khoom siv.Txhua hom khoom muaj nws tus yam ntxwv,

Qhov zoo, thiab qhov tsis zoo.Yog li ntawd, nws yog ib qho tseem ceeb uas yuav tsum xaiv cov khoom tsim nyog rau cov ntawv thov tshwj xeeb thiab cov qauv tsim.Kev txhaj tshuaj molding tuaj yeem ua ke nrog lwm cov txheej txheem, xws li ntxig molding, overmolding, thiab kev txhaj tshuaj, los tsim cov khoom siv ntau yam. los yog cov khoom siv ntau xim.Kev txhaj tshuaj molding yog txoj hauv kev nrawm, ua haujlwm tau zoo, thiab tus nqi tsim nyog los tsim cov khoom zoo.

Kev txhaj tshuaj molding yog dab tsi?

Kev txhaj tshuaj molding yog txheej txheem tsim khoom uas tsim cov khoom yas los ntawm kev txhaj tshuaj molten rau hauv pwm.Cov txheej txheem muaj plaub theem tseem ceeb: clamping, txhaj tshuaj, txias thiab ejection.

Clamping: Cov pwm yog tsim los ntawm ob lub halves, hu ua kab noj hniav thiab cov tub ntxhais, uas txuas nrog rau chav clamping.Lub tshuab clamping tuav cov pwm kaw nyob rau hauv siab thaum lub sij hawm txhaj tshuaj thiab txias theem.Lub zog clamping nyob ntawm qhov loj thiab cov duab ntawm ib feem, nrog rau cov khoom siv.

Txhaj Tshuaj: Cov khoom siv yas, feem ntau yog nyob rau hauv daim ntawv ntawm pellets los yog granules, yog pub rau hauv ib lub rhuab chim, qhov twg nws yog melted thiab sib tov los ntawm ib tug rotating ntsia hlau.Cov ntsia hlau kuj ua raws li lub plunger, thawb cov yas molten rau hauv pwm los ntawm lub nozzle.Kev txhaj tshuaj nrawm, siab thiab kub yog tswj xyuas kom ntseeg tau tias cov khoom ntim cov pwm tag nrho thiab sib npaug.

Txias: Cov yas molten hauv pwm pib txias thiab khov kho, noj cov duab ntawm ib feem.Lub sijhawm txias yog nyob ntawm qhov tuab thiab geometry ntawm ib feem, nrog rau cov khoom siv.Thaum lub sij hawm no, cov pwm tseem kaw thiab nyob rau hauv lub siab los tiv thaiv shrinkage los yog deformation.

Ejection: Tom qab ib feem tau txias txaus, cov pwm qhib thiab ib feem raug tshem tawm los ntawm lub tshuab hu ua ejector system.Lub ejector system tuaj yeem yog tus pins, cov hniav lossis cov dav hlau cua uas thawb ib feem ntawm cov pwm.Tom qab ntawd cov khoom raug tshem tawm ntawm lub tshuab thiab tshuaj xyuas kom zoo.

Kev txhaj tshuaj molding yog ib qho txheej txheem ntau yam thiab muaj txiaj ntsig uas tuaj yeem tsim qhov nyuaj thiab ua tau zoo nyob rau hauv ntau qhov ntau thiab tsis muaj pov tseg.Nws yog dav siv nyob rau hauv ntau yam lag luam, xws li automotive, kev kho mob, cov khoom siv, electronics thiab lwm yam.

Dab tsi yog qhov tseem ceeb thiab lub luag haujlwm ntawm kev txhaj tshuaj pwm?

Kev txhaj tshuaj molding yog cov txheej txheem tsim khoom siv dav siv uas tuaj yeem tsim cov khoom yas nrog cov duab nyuaj thiab siab precision.Txhaj tshuaj molding yuav tsum txhaj cov yas molten rau hauv pwm kab noj hniav, qhov chaw uas nws txias thiab solidifies rau hauv cov duab uas xav tau.Cov kab noj hniav pwm feem ntau yog ua los ntawm cov hlau lossis ceramic, thiab tuaj yeem tsim los tsim ntau qhov chaw ib zaug.

Qhov tseem ceeb thiab lub luag haujlwm ntawm kev txhaj tshuaj molding yog qhov tseem ceeb hauv ntau qhov kev lag luam, xws li tsheb, kev kho mob, aerospace, khoom siv hluav taws xob, thiab lwm yam.Kev txhaj tshuaj molding tuaj yeem muab ntau yam zoo, xws li:

- Kev ua haujlwm siab ntau: Kev txhaj tshuaj molding tuaj yeem tsim cov khoom loj hauv lub sijhawm luv luv, nrog cov khib nyiab tsawg thiab cov khoom seem.Kev txhaj tshuaj molding tshuab tuaj yeem ua haujlwm tsis tu ncua, thiab tuaj yeem ua haujlwm tau los txo cov nqi zog thiab kev ua haujlwm ntawm tib neeg.

- Kev ua tau zoo thiab sib xws: Kev txhaj tshuaj molding tuaj yeem tsim qhov chaw nrog qhov tseeb qhov tseeb thiab qhov chaw tiav, nrog rau cov khoom sib xws thiab kev ua haujlwm.Kev txhaj tshuaj molding tuaj yeem txo qhov tsis xws luag thiab kev hloov pauv hauv cov khoom kawg, los ntawm kev tswj qhov kub, siab, thiab ceev ntawm cov txheej txheem txhaj tshuaj.

- Kev tsim qauv yooj yim: Kev txhaj tshuaj molding tuaj yeem tsim qhov chaw nrog cov duab geometry nyuaj, cov ntsiab lus sib txawv, thiab ntau xim lossis cov ntaub ntawv.Kev txhaj tshuaj molding tuaj yeem ua raws li cov kev hloov pauv hauv kev tsim lossis kev qhia tshwj xeeb ntawm cov khoom, los ntawm kev hloov kho pwm kab noj hniav lossis siv cov ntaub ntawv yas sib txawv.

- Tus nqi zoo: Kev txhaj tshuaj molding tuaj yeem txo tus nqi tag nrho ntawm kev tsim khoom, los ntawm kev siv cov khoom siv tsawg, txo cov kev sib dhos thiab kev ua tiav, thiab ua kom cov kav ntev thiab lub neej ntev ntawm cov khoom.

Txhaj tshuaj molding yog ntau yam thiab txhim khu kev qha tsim cov txheej txheem uas tuaj yeem ua tau raws li qhov xav tau ntawm ntau yam kev lag luam thiab kev siv.Txawm li cas los xij, kev txhaj tshuaj molding kuj muaj qee qhov kev sib tw thiab kev txwv, xws li:

- Kev nqis peev siab tshaj plaws: Kev txhaj tshuaj molding yuav tsum muaj tus nqi siab tshaj plaws rau kev tsim thiab ua cov pwm kab noj hniav, nrog rau kev yuav thiab tswj lub tshuab txhaj tshuaj molding.Cov kab noj hniav pwm feem ntau yog kho rau txhua qhov, thiab tuaj yeem kim thiab siv sijhawm los tsim.

- Kev xaiv cov khoom siv tsawg: Kev txhaj tshuaj molding tsuas yog siv cov ntaub ntawv thermoplastic uas tuaj yeem yaj thiab ntws hauv qhov kub thiab txias.Qee cov ntaub ntawv thermoset lossis cov ntaub ntawv sib xyaw yuav tsis haum rau kev txhaj tshuaj molding, lossis tej zaum yuav xav tau cov khoom siv tshwj xeeb lossis kev kho mob los txhim kho lawv cov pwm.

- Kev cuam tshuam ib puag ncig: Kev txhaj tshuaj molding tuaj yeem tsim ntau cov khoom siv hluav taws xob pov tseg thiab emissions thaum lub sij hawm melting thiab txias ntawm cov khoom yas.Kev txhaj tshuaj molding tuaj yeem tsim cov khoom pov tseg yas los ntawm cov khoom siv ntau dhau uas tawm ntawm cov pwm kab noj hniav los yog cov ntaub ntawv nyob ib ncig ntawm cov npoo ntawm ib feem.Cov ntaub ntawv pov tseg no yuav tsum tau rov ua dua lossis pov tseg kom raug, txhawm rau txo lawv cov kev cuam tshuam ib puag ncig.

Kev txhaj tshuaj molding yog txheej txheem nyuaj thiab muaj zog uas yuav tsum tau ua tib zoo npaj, tsim, thiab ua kom zoo.Kev txhaj tshuaj molding engineers yuav tsum xav txog ntau yam, xws li:

- Kev xaiv cov khoom siv: Kev xaiv cov khoom siv yas cuam tshuam rau cov khoom, kev ua tau zoo, cov tsos, thiab cov nqi ntawm qhov kawg.Cov khoom siv yas yuav tsum ua raws li qhov yuav tsum tau ua ntawm qhov kev ua haujlwm, ib puag ncig, kev zoo nkauj, thiab kav ntev.Cov khoom siv yas yuav tsum muaj cov dej ntws zoo, ruaj khov, shrinkage, thiab sib haum nrog cov kab noj hniav pwm.

- Pwm tsim: Cov qauv tsim ntawm pwm kab noj hniav txiav txim siab cov duab, qhov loj, qhov zoo, thiab qhov nyuaj ntawm qhov kawg.Cov kab noj hniav pwm yuav tsum muaj qhov cua txaus, cua txias, ejecting, thiab clamping systems, kom ntseeg tau tias cov txheej txheem txhaj tshuaj du thiab zoo.Lub pwm kab noj hniav yuav tsum muaj cov qauv tsim nyog, phab ntsa thicknesses, kam rau ua, thiab nto tiav, kom tsis txhob muaj qhov tsis xws luag thiab deformations hauv qhov kawg.

- Cov txheej txheem tsis: Cov txheej txheem ntawm cov txheej txheem txhaj tshuaj cuam tshuam rau tus cwj pwm ntws, tus nqi txias, kev faib tawm siab, thiab crystallization ntawm cov khoom yas.Cov txheej txheem tsis yuav tsum tau hloov kho kom zoo dua qhov filling, packing, tuav, txias, thiab ejecting theem ntawm cov txheej txheem txhaj.Cov txheej txheem tsis tseem ceeb yuav tsum tau saib xyuas thiab tswj xyuas kom muaj kev sib luag thiab zoo hauv cov khoom kawg.

Kev txhaj tshuaj molding yog cov txheej txheem tsim muaj zog thiab nrov uas tuaj yeem tsim cov khoom yas zoo nrog ntau cov duab thiab ua haujlwm.Kev txhaj tshuaj molding plays lub luag haujlwm tseem ceeb hauv ntau qhov kev lag luam uas vam khom cov khoom yas rau lawv cov kev ua tau zoo thiab cov txiaj ntsig.Txhaj tshuaj molding kuj yog ib qho nyuaj thiab hloov zuj zus cov txheej txheem uas yuav tsum tau tas li innovation thiab txhim kho kom tau raws li cov kev hloov pauv thiab kev xav tau ntawm cov neeg siv khoom.